Data Centres Advancement: The Evolution of Liquid Cooling Technologies

In today’s world, data centres serve as the backbone of our digital infrastructure. As the demand for seamless connectivity, enhanced security, and increased computational power continues to grow, engineers are at the forefront of shaping the future of data centres. With environmental sustainability as a global imperative, the focus is on designing data centres with minimal carbon footprints. From advanced cooling systems to energy-efficient hardware, sustainable infrastructure is pivotal. This blog delves into the innovations driving advanced cooling systems, crucial for the next generation of sustainable data centres.

The increasing energy consumption of data centres is making traditional air-cooling methods redundant. Advanced liquid cooling provides two main benefits:

- increased energy efficiency, and

- the ability to achieve higher levels of server density which in turn leads to a more compact and space-efficient design.

Background

By utilising liquid cooling, data centres can significantly reduce the amount of energy required to keep servers cool

As liquids have a higher heat capacity and thermal conductivity than air, this allows for faster and more effective heat removal. By utilising liquid cooling, data centres can significantly reduce the amount of energy required to keep servers cool, ultimately leading to cost savings and a more sustainable operation.

Additionally, liquid cooling technology can also potentially extend the lifespan of servers and other hardware components by keeping them at lower operating temperatures. This could result in reduced maintenance costs and a longer overall lifespan for the equipment, ultimately providing a better return on investment for datacentre operators.

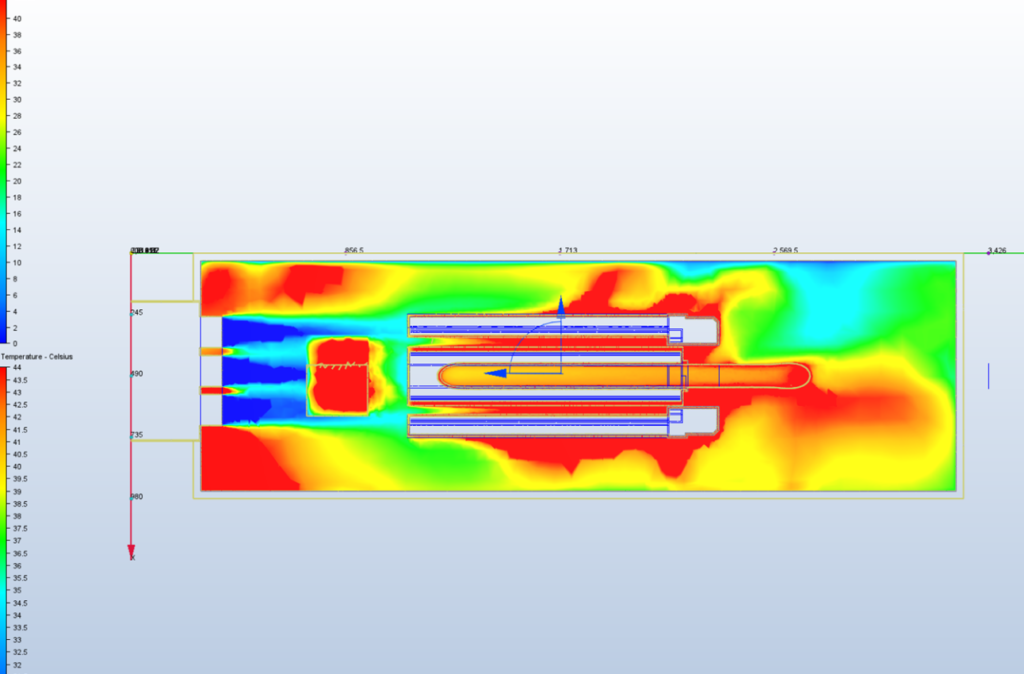

There are three primary types of liquid cooling:

- Indirect liquid cooled – heat is transferred to liquid through an air-to-water heat exchanger located within a row or cabinet

- Direct liquid-cooled – heat is transferred to an attached liquid-cooled component, such as a heat sink / cold plate or directly to a dielectric fluid such as in immersion cooling.

- Hybrid direct and indirect water-cooled – direct liquid cooling is used for specifically cooling components with the highest heat load and the balance of equipment is cooling using a secondary air-to-water cooling device.

Hybrid direct and indirect water-cooled is emerging as the forerunner in providing flexible solutions.

Coolant Distribution Units (CDUs) are key components in liquid cooling implementation which are required as interfaces between the facility cooling systems and IT equipment. CDUs allow datacentre operators to monitor and control key processing indicators such as pressure, temperature, and flowrate.

Ampromech have recently completed a feasibility study regarding the implementation of a direct-to-chip cooling system and its considerations for a 2.5MW and 10MW facility. The study was done in conjunction with Nexalus, Collen Construction, and Munters Ireland, and reviewed the impact in terms of PUE (Power Usage Effectiveness), energy savings, WUE (Water Usage Effectiveness), and overall space /footprint comparisons. In general, total energy savings of 20% were estimated and an overall 33% space reduction for the same IT load.

Table 1: PUE and WUE comparisons for air-cooled vs liquid-cooled facilities

| Traditional Air-Cooled Facility | Facility using liquid Direct-to-Chip Technology |

Power Usage Effectiveness (PUE) | 1.2 to 1.58 | 1.116 |

Water Usage Effectiveness | 1.8L per 1kWh | 0L per 1kWh |

The 33% saving on space for the same IT load is a considerable amount which has knock on positive impacts for both existing retrofits and greenfield sites. Existing facilities could use the reclaimed space for additional IT equipment or could potentially implement facility support infrastructure such as a BESS (Battery Energy Storage System) which would enable facilities to store energy from renewable sources and release them when required. For greenfield sites a smaller footprint results in less building materials required including concrete, steel, and insulation which are materials that heavily contribute to embodied carbon emissions.

Considerations

Ampromech recognises that the technology’s full potential is still being validated through ongoing research and deployment. Along with the obvious benefits of liquid cooling there are some considerations to be made as liquid cooling may not be the preferred technology for all cases. Whether a facility decides to go with traditional air-cooling or liquid-cooling will be on a case-by-case basis and there are different constraints to be considered for greenfield and existing sites:

Cost: Liquid cooling systems can be expensive to install and maintain compared to traditional air-cooling systems.

Complexity: Liquid cooling systems are more complex to design, install, and manage than air cooling systems, requiring specialised expertise.

Risk of leaks: Liquid cooling systems can pose a risk of leaks, which can potentially damage expensive equipment and disrupt operations. This is generally mitigated through proper design.

Maintenance requirements: Liquid cooling systems require regular maintenance to ensure optimal performance, including monitoring fluid levels, checking for leaks, and replacing components as needed.

Compatibility issues: For existing facilities some servers and other equipment may not be compatible with liquid cooling systems, requiring additional investment or modifications to be made.

Conclusion

This review highlights the advantages and considerations surrounding the potential of advanced liquid cooling technologies to enhance data centre sustainability and efficiency. Ongoing research and implementations at larger scales is crucial for overcoming existing challenges and unlocking these technologies’ full potential.

For more detailed technical insights and comprehensive data, refer to Status of Liquid Cooling of Data Centres: Some Answers and Some Questions – A.J. Robinson PhD: https://www.nexalus.com/wp-content/uploads/2023/07/Status-of-Liquid-Cooling-of-Data-Centres.pdf

ENGINEERING THE FUTURE

Related Blogs

- Electrical Engineering

- Electrical Engineering

- TECHNOLOGY

- Regulations