The Crucial Role of Arc Flash Analysis in Ensuring Electrical Safety

Arc flash incidents pose severe risks to personnel and equipment in various industrial settings. Understanding and mitigating these risks through comprehensive Arc Flash Analysis is paramount for maintaining a safe and compliant workplace. This blog post examines details of arc flash hazards, the methodology of Arc Flash Analysis, and its significance in ensuring electrical safety.

Understanding Arc Flash

An arc flash is a rapid release of energy due to an arcing fault between electrical conductors. This phenomenon can result in extreme temperatures, intense light, and a pressure wave, causing severe burns, blindness, hearing loss, and even fatalities. The potential for damage to electrical equipment is also significant, often leading to prolonged downtime and costly repairs.

Why Arc Flash Analysis is Essential

Arc Flash Analysis is a systematic approach to identifying potential arc flash hazards and implementing measures to mitigate these risks.

The process is critical for several reasons:

- Protecting Personnel: The primary objective of Arc Flash Analysis is to protect individuals working on or near electrical equipment. By identifying hazard levels, appropriate Personal Protective Equipment (PPE) can be specified to ensure the safety of workers.

- Compliance with Standards: Adhering to standards such as IEEE 1584 and NFPA 70E is not only a regulatory requirement but also a best practice for maintaining a safe working environment.

- Minimising Equipment Damage: Effective Arc Flash Analysis helps in designing protective measures that safeguard equipment, thereby reducing the risk of damage and ensuring continuity of operations.

Components of Arc Flash Analysis

Arc Flash Analysis involves several key steps, each critical for a thorough understanding and mitigation of arc flash hazards.

Data Collection

The process begins with meticulous data collection. This involves gathering detailed information about the electrical system, including:

- Equipment specifications

- System configuration

- Operating conditions

- Maintenance records

Accurate data collection is essential as it forms the foundation of the entire analysis process.

Fault Current Calculation

Next, the available fault current at various points in the system is calculated. This step is crucial for assessing the potential for arc flash incidents and determining the magnitude of these events.

Incident Energy Analysis

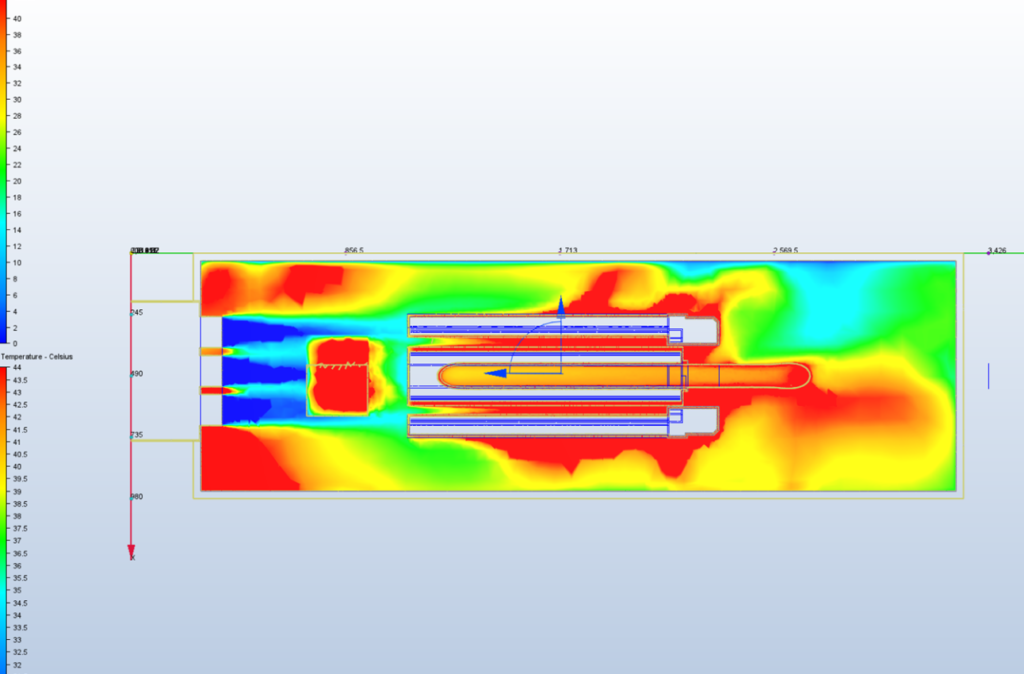

The core of Arc Flash Analysis is the calculation of incident energy, which determines the severity of an arc flash. This analysis involves complex calculations to estimate the energy released during an arc flash, expressed in calories per square centimetre (cal/cm²). The energy released is dependent upon the available fault currents and time / duration for which this current is present. The results of this analysis help in determining the appropriate PPE and safety measures required.

Labelling and Documentation

Once the analysis is complete, equipment must be properly labelled with arc flash hazard information. Comprehensive documentation is also necessary to ensure ongoing safety and compliance. This includes maintaining records of the analysis, updating them regularly, and ensuring that all personnel are aware of the hazards and safety measures.

Mitigation Strategies

Several strategies can be employed to mitigate arc flash hazards effectively:

Using Suitably Certified & Rated Switchgear: In the design phase, selection of switchgear must take into account the potential fault currents that could feed the fault within the switchgear. Switchgear built to applicable European standards are designed to contain any arc flash within the equipment itself. The risk arises if switchgear is open for maintenance or if doors and enclosures are left not properly secured.

Using Current-Limiting Devices: Installing current-limiting fuses and circuit breakers can significantly reduce the energy released during an arc flash, thereby minimising the risk.

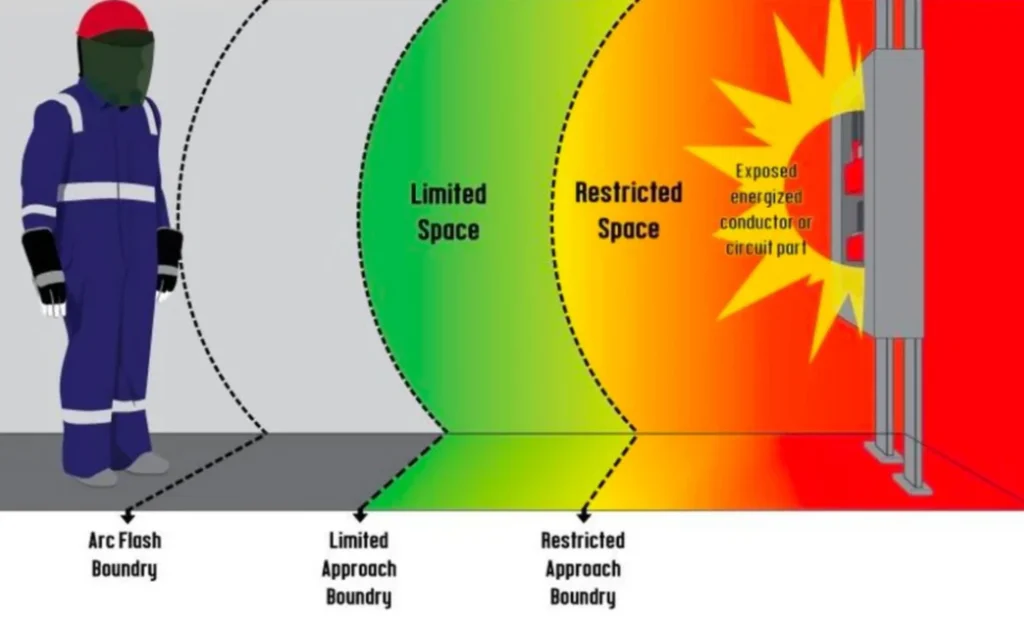

Maintaining Safe Working Distances: Establishing and enforcing safe working distances can help protect personnel from the effects of an arc flash. This involves clear labelling and training to ensure compliance.

Implementing Protective Relaying: Advanced protective relaying can detect and isolate faults quickly, reducing the duration and severity of an arc flash incident.

Regular Training and Awareness Programs: Continuous training and awareness programs for employees are crucial. These programs should focus on recognising hazards, using PPE correctly, and following safety procedures.

Conclusion

Arc Flash Analysis is a vital component of electrical safety, providing the foundation for identifying and mitigating arc flash hazards. By understanding the intricacies of this process and implementing the necessary safety measures, organisations can protect their personnel, ensure compliance with standards, and minimise the risk of equipment damage. As industries continue to evolve, the importance of comprehensive Arc Flash Analysis will only grow, making it an indispensable tool for maintaining safety and efficiency in electrical systems.

ENGINEERING THE FUTURE

Related Blogs

- Data Centre, TECHNOLOGY

- Electrical Engineering

- TECHNOLOGY

- Regulations