Unlocking the Potential of Computational Fluid Dynamics (CFD)

Computational Fluid Dynamics (CFD) is a transformative technology in engineering, providing detailed insights into the behaviour of fluids—both liquids and gases—as they interact with solid surfaces and flow through or around three-dimensional structures. By solving complex mathematical equations that govern fluid flow, heat transfer, mass transfer, and chemical reactions, CFD offers a powerful numerical method for predicting these intricate processes.

What is Computational Fluid Dynamics?

CFD leverages advanced computational techniques to model and simulate fluid behaviour under various conditions.

Advantages of CFD

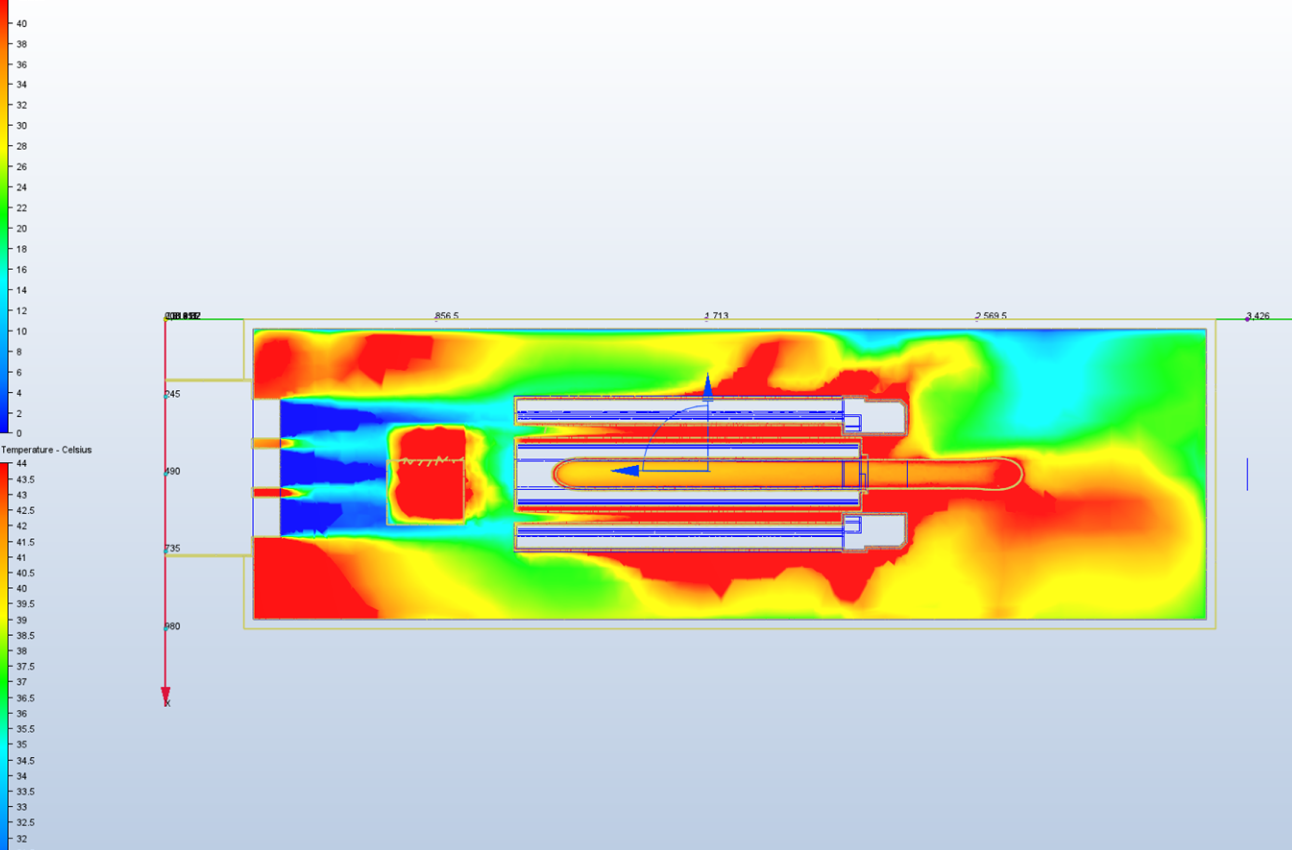

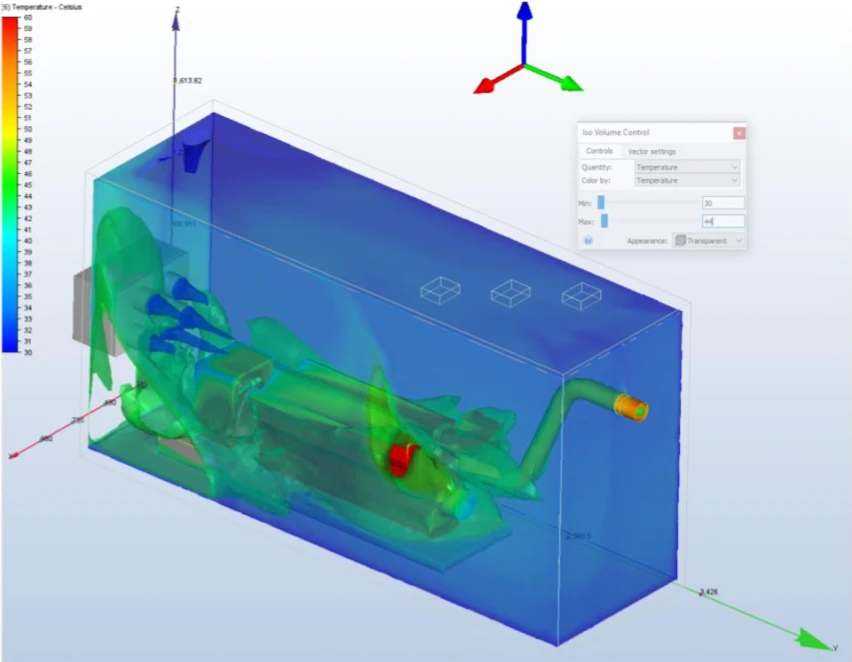

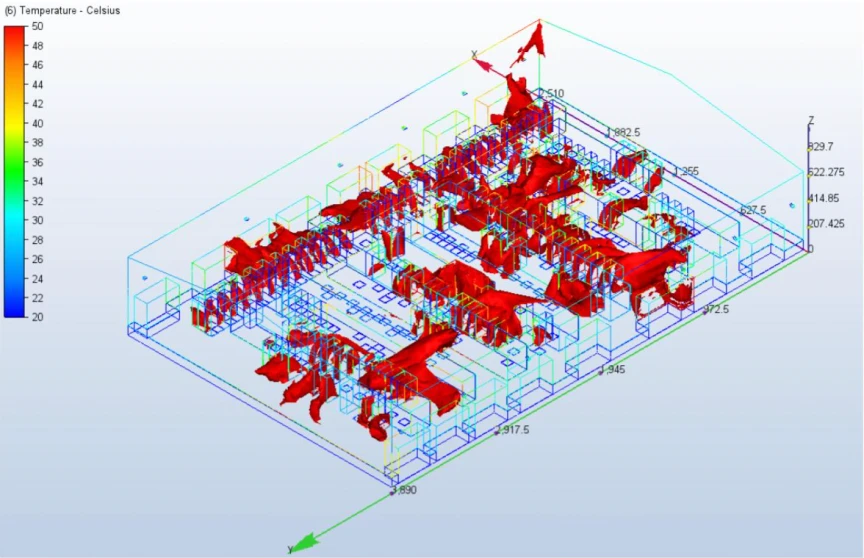

- Predictive Analysis: CFD excels at anticipating outcomes that are not immediately visible, providing a detailed perspective on fluid dynamics within specific environments, such as data centres. It can highlight any potential hotspots which can impact server air-on temperatures and thereby affect contracts and guarantees.[1].

- Cost Efficiency: By reducing the need for physical prototypes, CFD simulations save both time and money compared to traditional experimental methods [2][3].

- Deeper Insights: CFD allows engineers to gain a profound understanding of flow behaviours and physical phenomena within a system, facilitating informed engineering decisions [1].

- Safety Evaluations: It aids in assessing the safety of designs and identifying potential hazards, thus enabling proactive risk management [4].

- Design Flexibility: Engineers can explore a vast array of design scenarios with CFD, optimizing for performance, efficiency, or reduced emissions [1][2].

- Visual Interpretation: CFD provides visual representations of flow patterns, making it easier to comprehend complex flow systems than with traditional experiments [3].

- Sustainable Design: CFD allows for improved prediction of airflow requirements and can determine real-time heat transfer. This capability assists sustainability in that it can accurately predict maximum and minimum limits and therefore prevent the historic over-sizing of equipment, leading to needless waste loss of operational efficiency.

Applications of CFD

Engineering Design: Improve design layouts and simplify maintenance and repair processes.

Data Centres: Enhance IT troubleshooting and support retro-commissioning efforts with detailed airflow analysis [4].

Process Safety: Evaluate the effects of gas leaks and dispersion rates in processing areas to ensure safety and compliance [1].

Environmental Impact: Model and mitigate the environmental impact of emissions and other pollutants [3].

Real-World Case Studies

- Data Centres: CFD has been instrumental in optimizing airflow and cooling strategies in data centres, leading to significant energy savings and improved system reliability. By modelling various IT configurations, CFD provides a granular view of expected outcomes, ensuring that each data centre’s unique design is effectively managed [1][4].

- Power Generation, Oil and Gas Industry: Where pressurised gases are stored or transmitted, CFD is used to model the behaviour of gases in the event of leakages and controlled venting. This helps in optimising equipment locations, including vales and flanges to ensure that any emitted gas is safe and controlled.[2][4].

Conclusion

Computational Fluid Dynamics is a cornerstone technology in modern engineering, offering unparalleled insights and predictive capabilities. Its applications span numerous industries, providing essential tools for improving design, safety, and efficiency. As CFD technology continues to evolve, its integration with other advanced technologies will further enhance its value, making it an indispensable asset in the engineering toolkit.

At Ampromech, we are committed to leveraging the power of CFD to deliver innovative solutions tailored to your specific needs. Whether you are optimising a data centre, ensuring process safety, or addressing environmental concerns, our expertise in CFD can help you achieve your goals. Contact us today to learn more about how we can assist you with your CFD needs.

For further reading and detailed technical insights, refer to the comprehensive studies and case examples available in the latest engineering journals and industry publications.

References

- KETIV. “What is Computational Fluid Dynamics (CFD) and Why You Need It.” Retrieved from https://ketiv.com/blog/what-is-computational-fluid-dynamics-and-why-you-need-it/

- Piping and Interface Engineering. “Computational Fluid Dynamics in Piping: Meaning, Uses, Benefits, Software.” Retrieved from https://pipingandinterface.com/computational-fluid-dynamics-in-piping/

- SimScale. “Computational Fluid Dynamics (CFD) – Ultimate Guide.” Retrieved from https://www.simscale.com/docs/simwiki/cfd-computational-fluid-dynamics/

- GoEngineer. “Computational Fluid Dynamics (CFD): Applications & Solutions.” Retrieved from https://community.goengineer.com/forums/topic/1149-computational-fluid-dynamics-cfd-applications-solutions/

- Spatial Blog. “13 Key Applications of CFD Simulation and Modeling.” Retrieved from https://blog.spatial.com/13-key-applications-of-cfd-simulation-and-modeling

ENGINEERING THE FUTURE

Related Blogs

- Data Centre, TECHNOLOGY

- Electrical Engineering

- Electrical Engineering

- Regulations